The technology applies protective interior coatings of cylinders for the automotive, chemical, oil and gas and power industries.

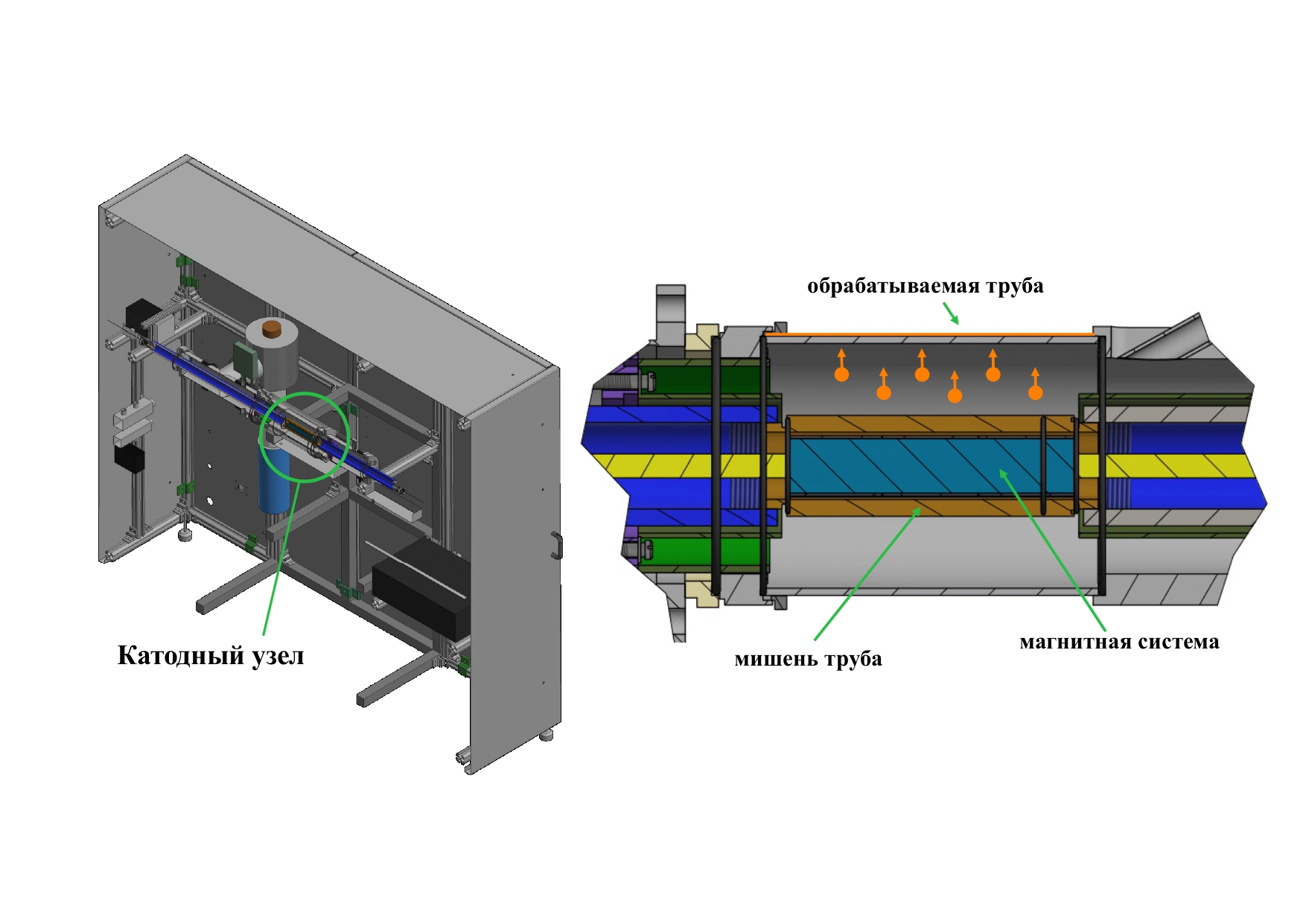

The unit consists of a cylindrical process chamber with a pumping station for reduced pressure. A hollow workpiece is used as a vacuum chamber. When a tube inside the chamber is irradiated with ions by plasma immersion ion implantation, the material it is made of is spattered and deposited onto the inner walls of the cylinder (workpiece). To form complex coatings, reactive gases can be fed into the chamber. A rotating magnetic system is used to uniformly produce cathode material and deposit a coating onto the inner surface of cylinders.